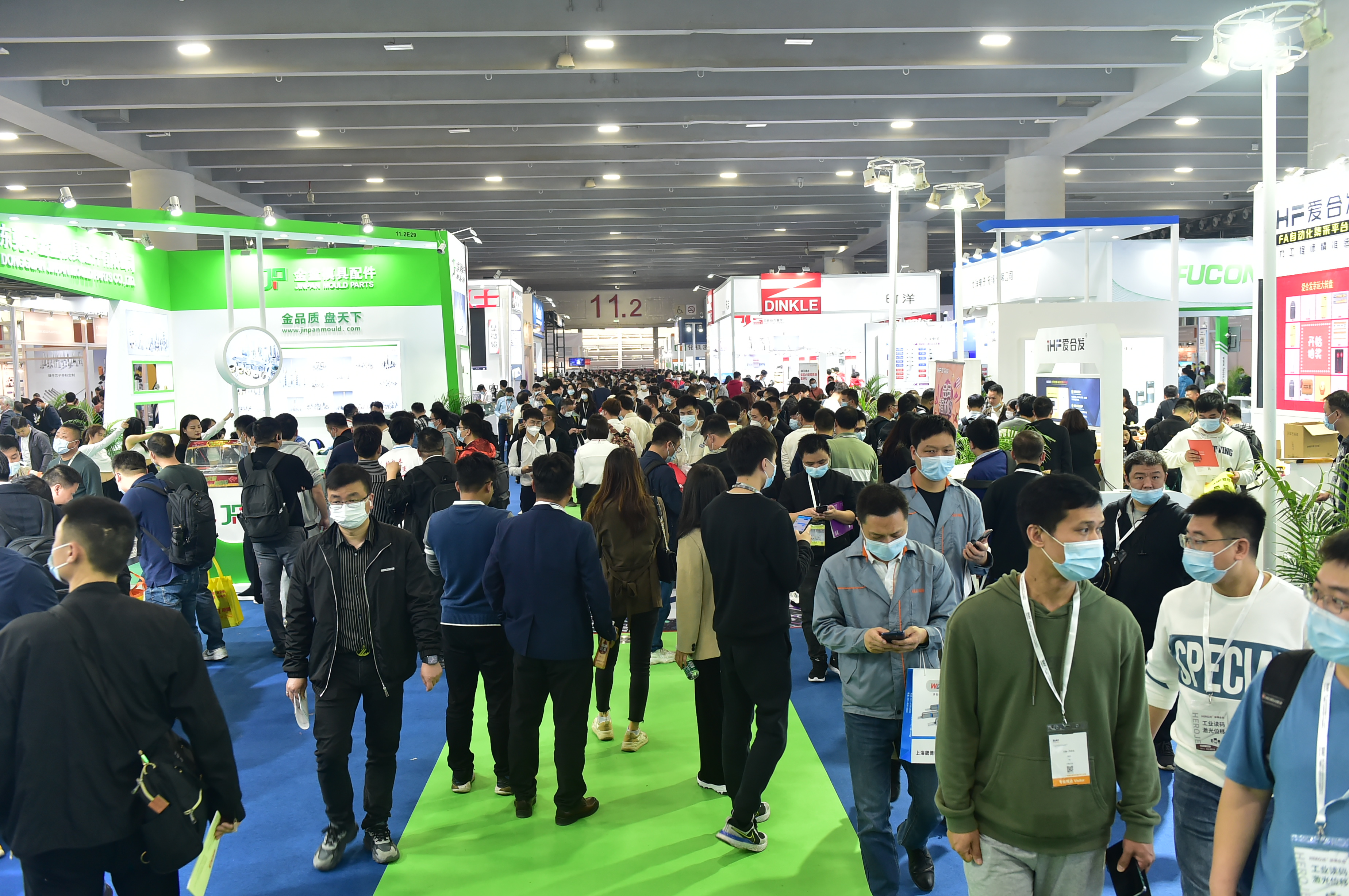

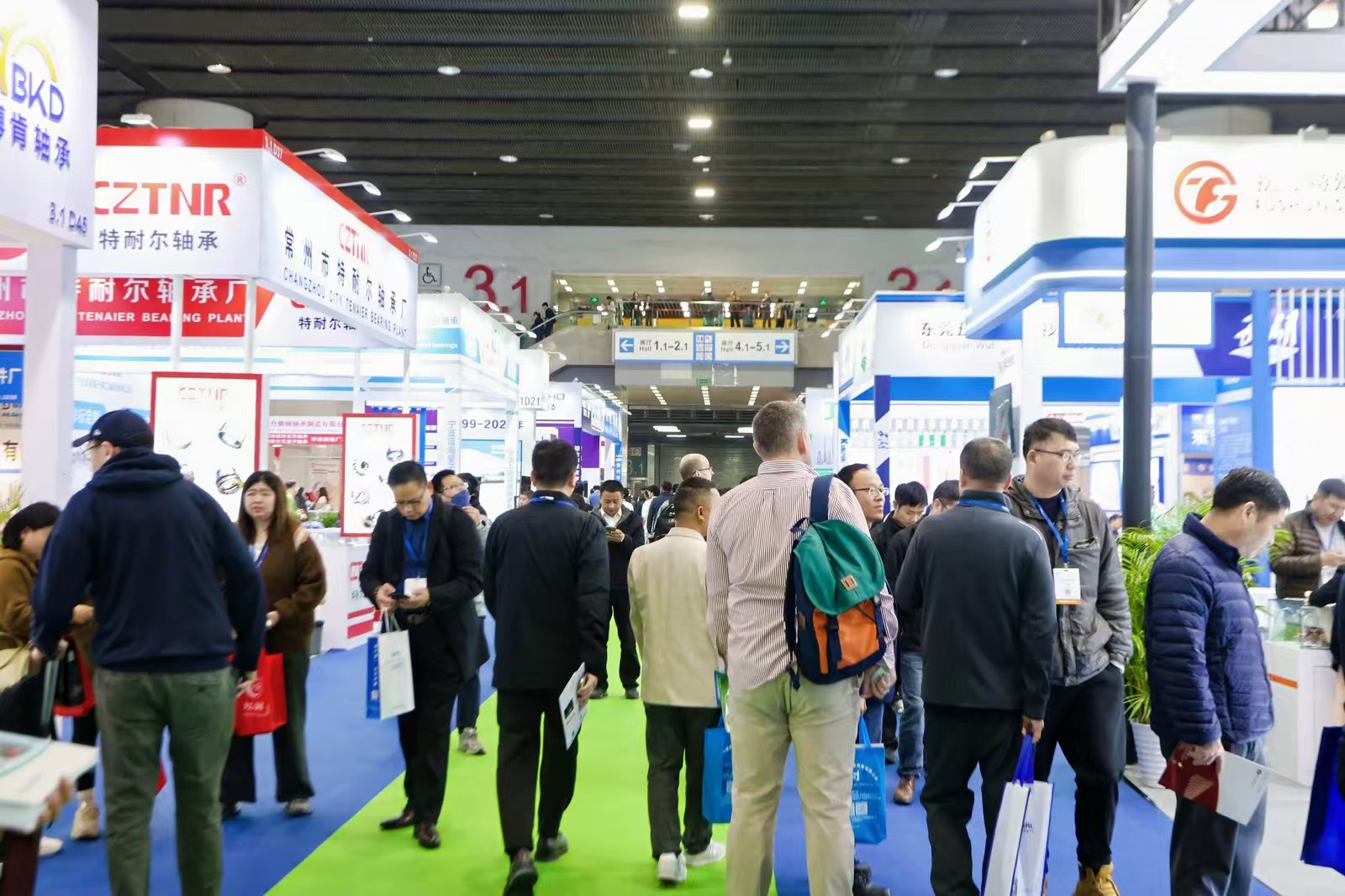

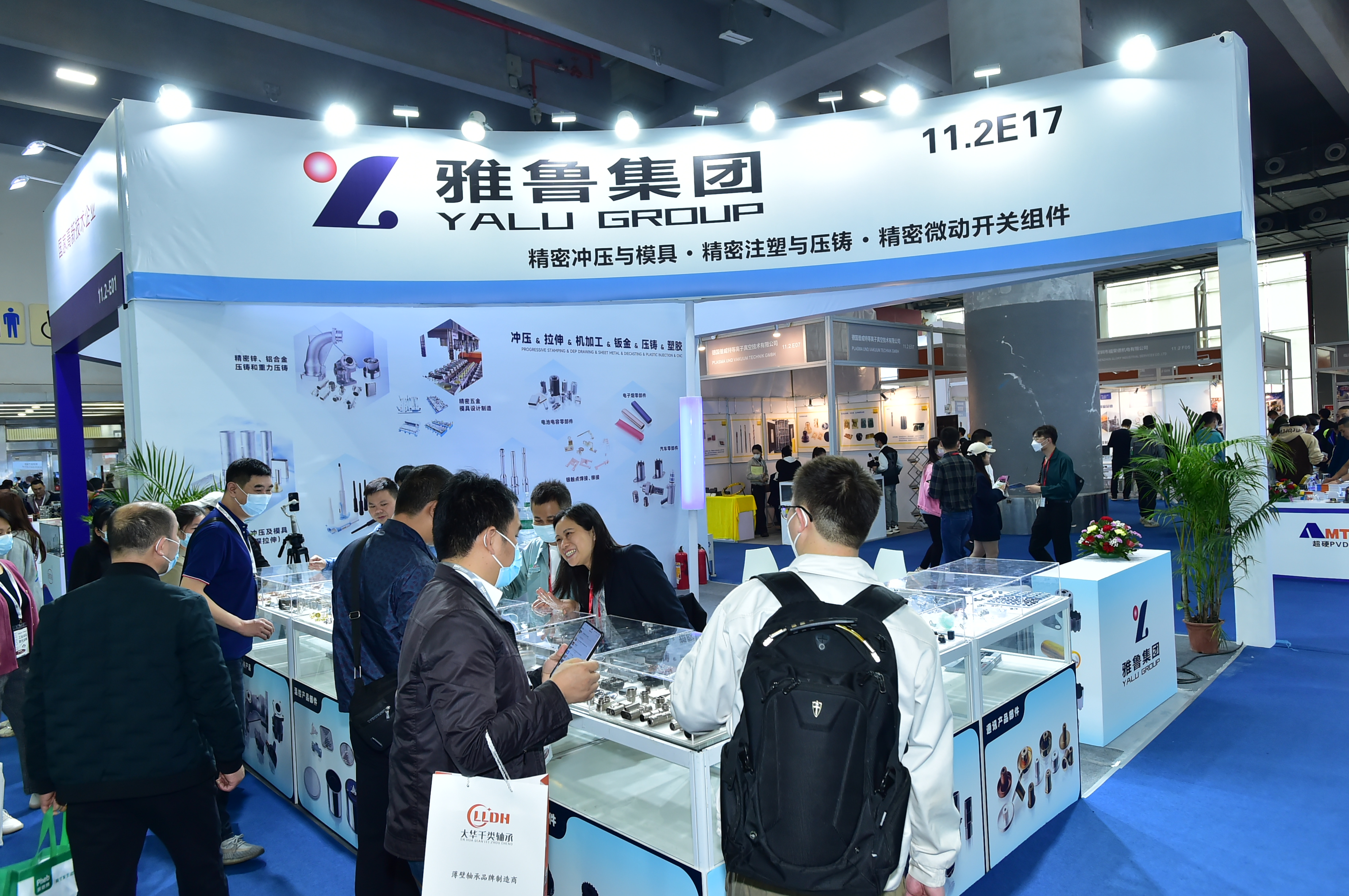

Asiamold Select – Guangzhou drew to a successful close on 27 February 2025, featured advancements in mould-making, die-casting, stamping, and 3D printing technologies, drawing visitors from across China and overseas. Exhibitors showcased high-precision equipment, advanced materials, and digitally-integrated manufacturing solutions that reflect the rigorous technical demands of modern mould-making.

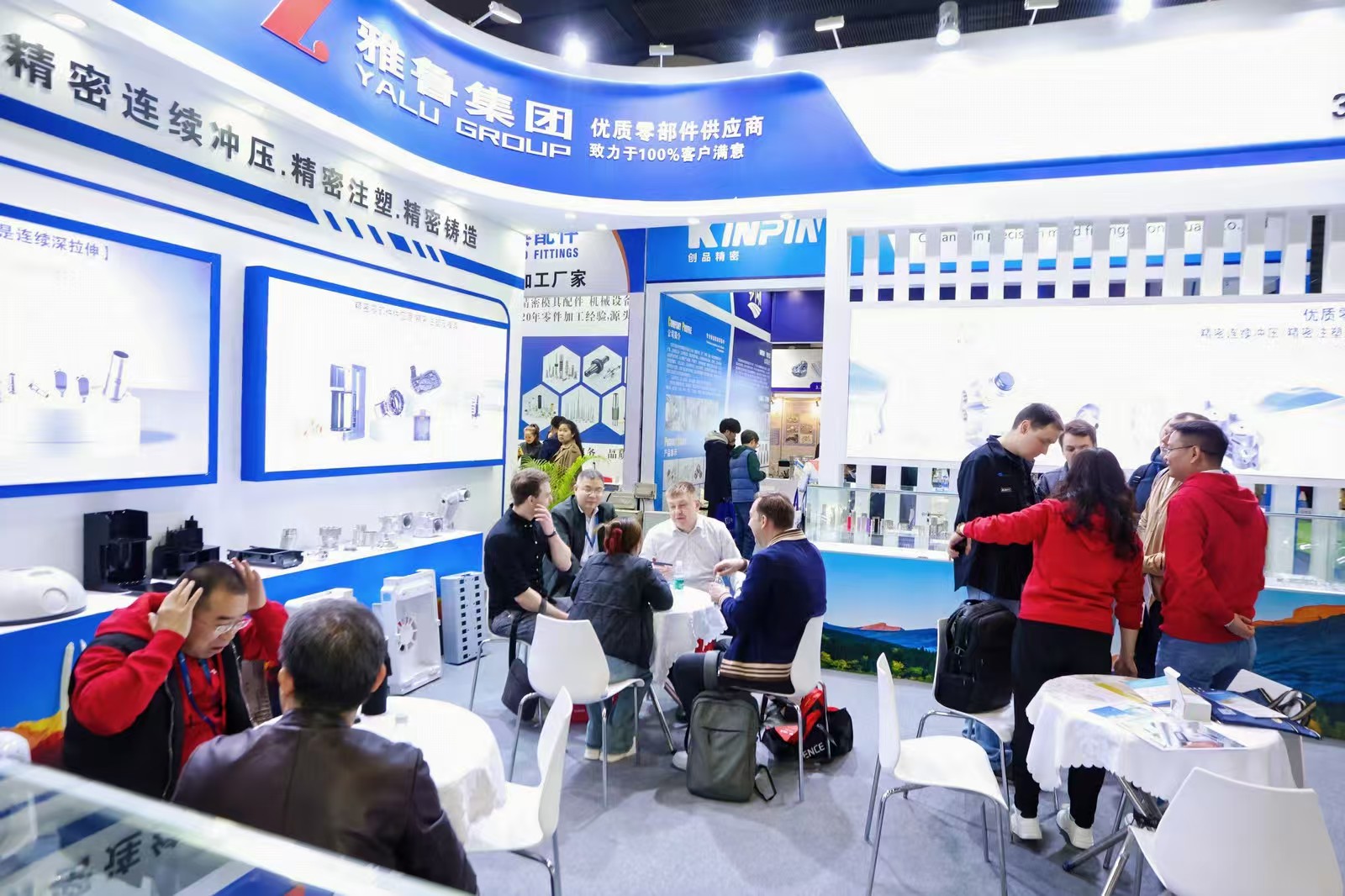

Visitor feedback highlighted the benefit of the concurrent exhibitions in offering a unified platform to explore digitally integrated solutions for a wide range of applications and industries, enabling attendees to address multiple production challenges efficiently in a single visit.

Download materials

- 2026 application form (docx, 444 KB)

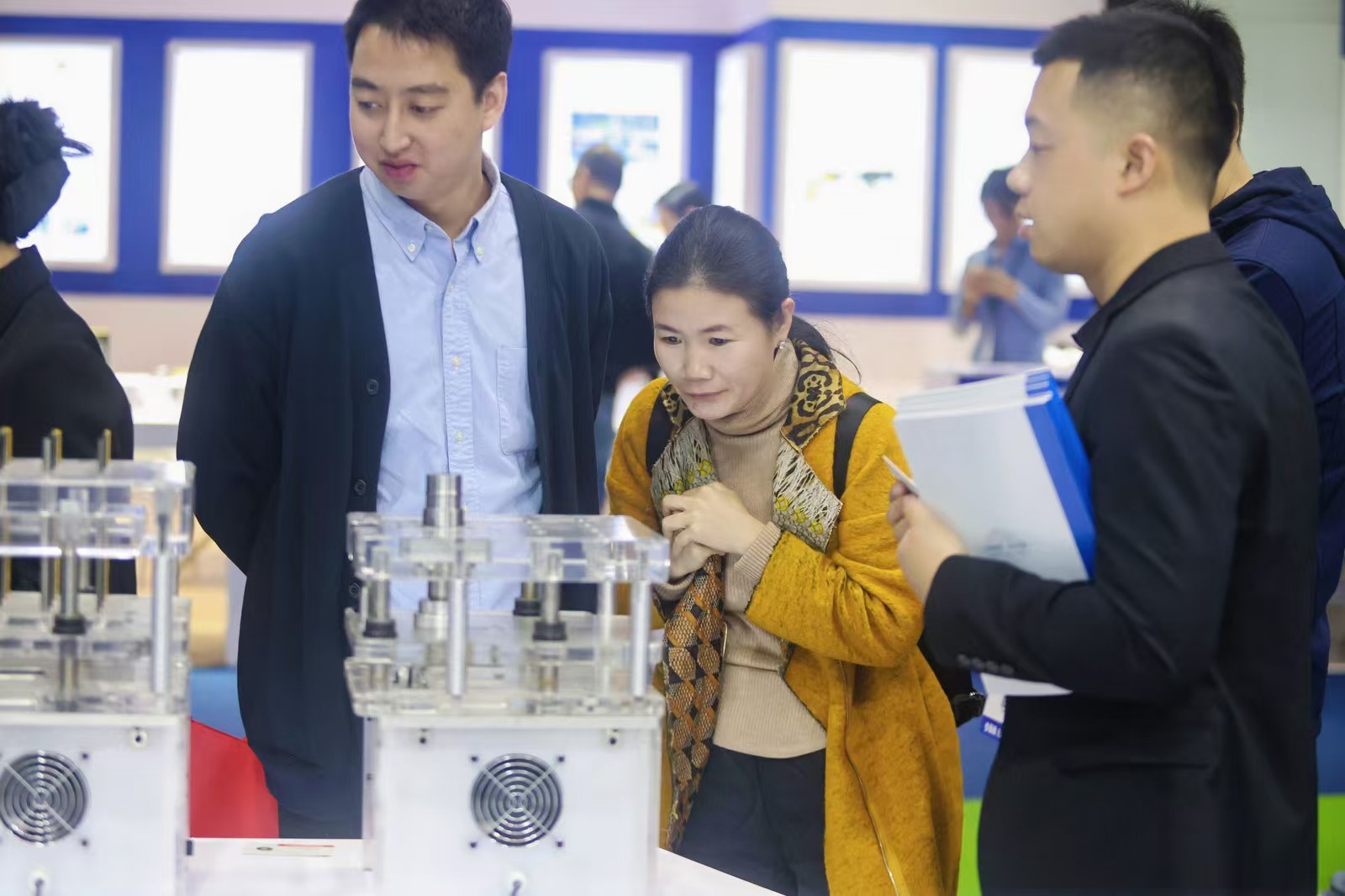

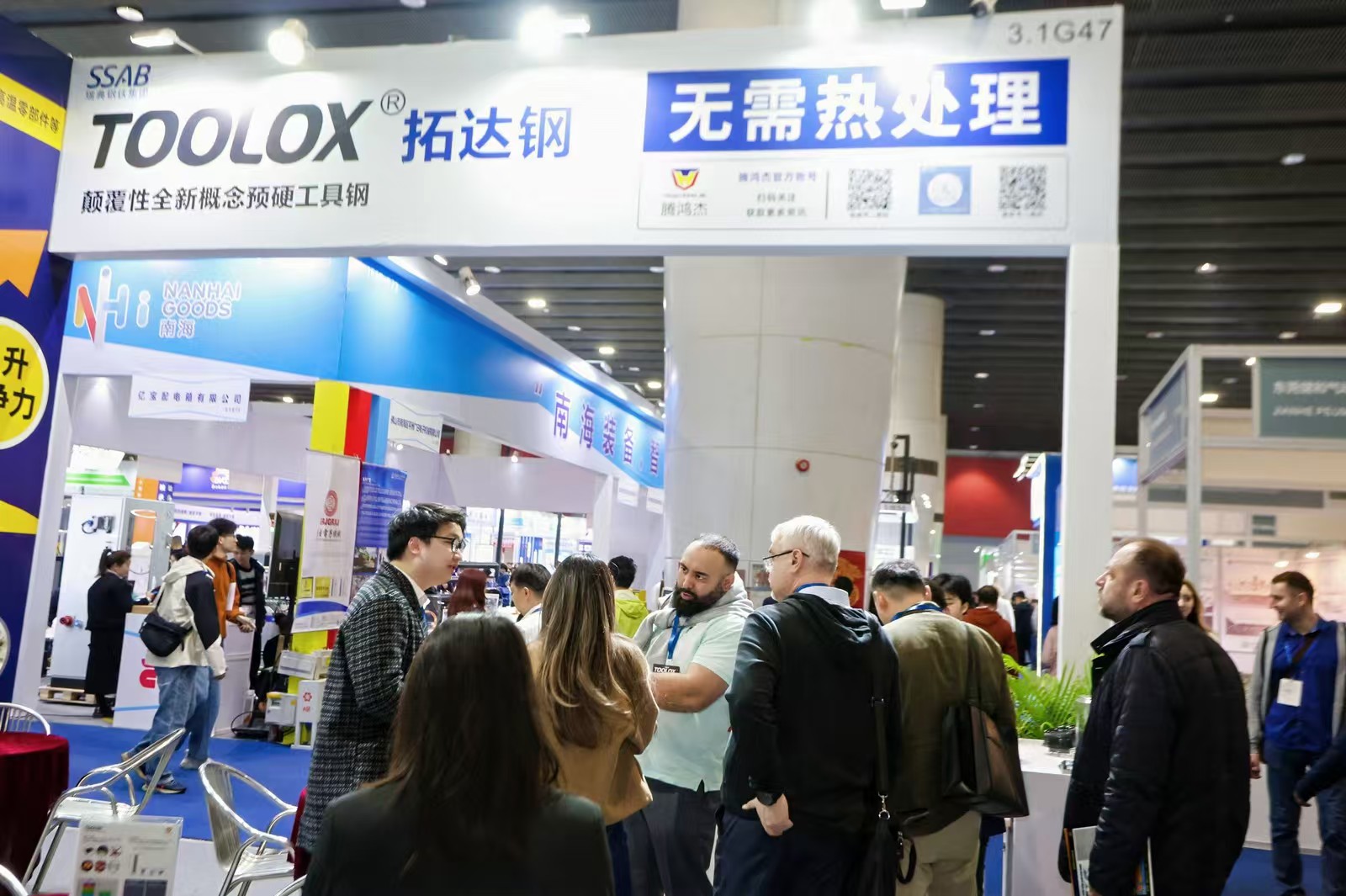

Show Impression

Browse through a selection of images capturing the variety of products, events and interactions at Asiamold Select – Guangzhou.